Great Interview on the Retigo combi oven’s 30th anniversary

Did you know that this year marked the 30th anniversary of the first combi oven produced? Maybe some readers even remember the company’s beginnings. But don’t be fooled. The first combi oven was made in 1993, but RETIGO s.r.o. wasn’t incorporated until a year later, in 1994. Its anniversary will therefore be celebrated in 2024.

Since that time, a lot has changed. That includes the design of combi ovens, expansion of the model ranges, remote control, tweaks to the appliances’ software, arrival of new employees and the expansion of the company premises. The most recent extension took place in 2021. The new hall has helped us expand production capacity. But let's linger for a moment to the time when the first combi oven was created, and the company soon after that. Let’s take a trip down Memory Lane with three of our five owners. Jiří Zátopek, Jaroslav Kudela and Libor Pavelka shared their facts and experience with us.

How did Retigo’s five current owners get together?

Zátopek: We all worked together at the old Tesla plant in Rožnov, where single-purpose machines were built.

Pavelka: Mr Zátopek and Mr Kudela worked in electrical design, and I worked in mechanical design with Jirka Jaroň and Vašek Miller, who are also Retigo owners.

Kudela: We were mainly friends at work. At the time, we worked on smokers. They’re similar to combi ovens. They heat up, there’s a control unit, a fan, but the temperatures aren’t that high, and smokers produce smoke.

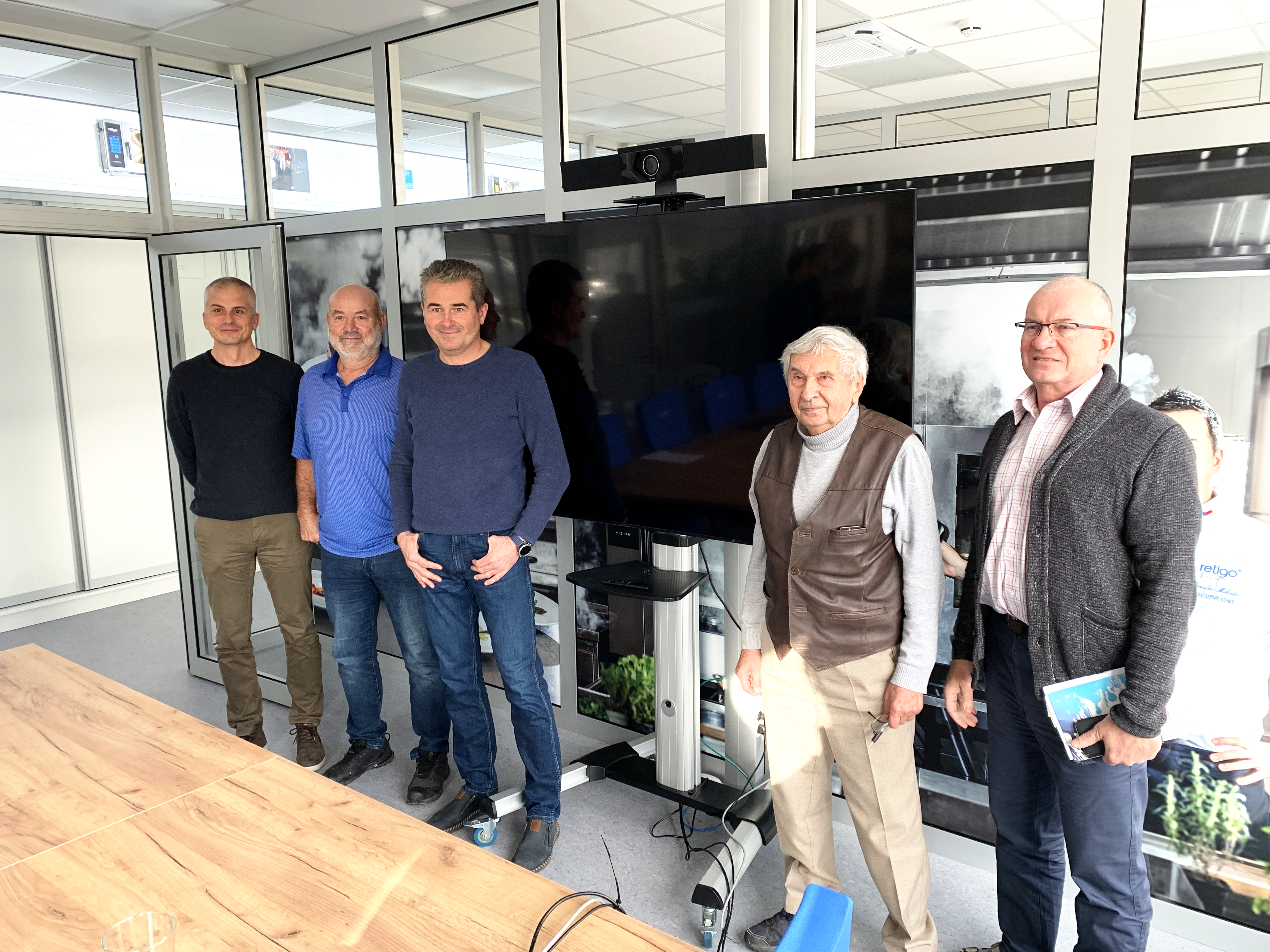

From the left: Norbert Pelc (Managing Director), owners: Václav Miller, Jaroslav Kudela, Jiří Zátopek, Libor Pavelka

Where did the idea come from to produce a combi oven?

Zátopek: After the revolution, Tesla understandably looked for other lines of business, and one of them was culinary technology, and we were tasked with putting together a combi oven.

Pavelka: Combi ovens didn’t succeed there, though, and we got the idea to produce a combi oven outside Tesla.

Zátopek: Tesla knew that marketing was what was missing, which is necessary when you have an idea and a product, but there was nobody selling the appliances. Nobody knew how to do it at the time, least of all the factory. So it “died”. And that was an opportunity to figure out what to do next.

Kudela: We liked the fact that the appliance was expensive and couldn’t be produced or copied easily. So at work we said we’d try to put it together. We were led to that by changes in the company and a less than positive outlook for the future. The plant sold only a couple of combi ovens, and in a few years was bankrupt.

Did you know what a combi oven was?

Kudela: I didn’t. I started gathering information and researching the market. We didn’t have any competition, just Eloma in Germany and one more manufacturer. Their combi ovens cost up to 300,000 crowns, which at the time was unimaginable — almost the price of a new house. These appliances already had some history, so after the revolution, they were among the first to start appearing.

How did the first combi oven come about?

Zátopek: We developed it in our free time. We spent the night on the design drawings and then in the morning we set to work. Then, based on the drawings, we contacted a small company that delivered the parts we needed.

Kudela: Even though our first meetings also took place at work. Once in a while a supervisor would come to see what was going on, so we’d always scatter, but otherwise it was pretty loose. We put the design together; everybody did something different.

Pavelka: Right, instead of spending time with the kids, we were designing a combi oven. We completed everything in Zátopek’s garage, but we got help with some things — metalworking, welding and all that. It was home production. Jirka Jaroň tested the appliance and cooked at home in his cellar. Putting the first unit together took several months, but I don’t remember exactly.

The first combi oven was produced by an association of entrepreneurs, and only then was Retigo s.r.o. established and hired its first employees [around mid-1994, ed.]. Well, actually, we five were the first employees.

About how much did it cost to make the first combi oven unit?

Zátopek: I’d say about 60,000 crowns, but I don’t remember exactly. We put the money together ourselves, but I felt a larger investment was needed. I put my own considerable savings into the company, along with money I earned in the United States. Of course, in America I spent half my money on petrol, because I wanted to see the country, but I invested the rest. I even started cramming English at 40. In America I also shot a documentary about the life of Czech expats and people who emigrated from Wallachia to Texas.

Where did you get your inspiration and ideas for the design?

Zátopek: We didn’t have anywhere to get inspiration, just that we’d made two types of combi ovens at Tesla, but otherwise we didn’t have anything. We had no known competition. Besides the two units from Tesla, we didn’t have any other combi oven to look at. We just built it by feel. We wanted to have a better, more modern combi oven than the Tesla ones — with no analogue controls, and with digital elements.

It all succeeded in the end.

Zátopek: In 1993, we were the first combi oven in the world. That combi oven, the Digital 611 model, is on display in the company exhibit near the cafeteria.

Pavelka: Right from the first unit, we had a computer-controlled appliance — no analogue elements, no buttons. It was a digital appliance, so we named it the Digital.

How did you sell your first combi oven?

Kudela: At the time, a Škoda Felicia car cost about 70,000 crowns. We sold our first appliance for double that, which was amazing, but there was a lot of work and time in it.

Pavelka: The first order was agreed to ahead of time; that was the first appliance. Zátopek is from Frenštát, and as you all know, the first combi oven went to the local hotel high school there.

Zátopek: After the sale of the first combi oven to the hotel school in Frenštát pod Radhoštěm, we financed the development of four more units. So the first five combi ovens were produced in my garage. Only later did we rent space at Tesla Rožnov, and then we bought the current building, which was in a miserable state. Starting the business required us to tighten our belts, as they say.

Pavelka: We always produced a certain number of combi ovens, and they sold out. As soon as they were sold, we could buy material and produce another series.

People didn’t know about combi ovens. How did you teach people to work with them, and how did you raise awareness?

Kudela: We drove around presenting the appliances, training and installing them ourselves. We couldn’t afford employees. I drew on competitors’ cookbooks. We’d drive up, take the combi oven to the kitchen, connect the drain, the water, and then I’d do training.

Pavelka: The kitchens used to have triple ovens from ALBA Hořovice, they provided all the equipment. We had to enlighten people on how a combi oven was better than an ordinary oven. Unlike the others, we didn’t have to import the products. Up to that time, we were the only domestic manufacturer of high-quality equipment.

Kudela: Traditional ovens had a spiral at top and bottom. A combi oven is a bit different. One clear thing was the lowering of the temperature. While they were used to cooking at 200°C, we cooked at 160°C and even added moisture. The results were always outstanding, crisp and thoroughly baked. Back then, most of our customers were school cafeterias.

Did you also try your luck at trade shows then?

Kudela: The first trade show was in Brno in 1994. Retigo s.r.o. didn’t exist yet as a company. We agreed that Mr Černý would share the space with us. He knew what business was, because he was Czech-Swiss. The space was supposed to cost us about 5,000 crowns, but in the end we didn’t pay anything, because Mr Černý liked the fact that we’d started something.

In those days we were still going normally to work. So I was thinking how to fix it so that I could be at the trade show with the combi oven and at work at the same time, I couldn't afford to skip work [laughs]. Finally, friends helped me work it so that I was formally at work but was actually at the trade show the whole time, nervously keeping a lookout for anyone I knew from work who might see me there [laughs]. We made some contacts at the trade show, and from that we sold four combi ovens in the first year. Later it was enough to spend 10,000 crowns on an advertisement, and from that we sold another one.

There was no e-mail, people didn’t phone, but we had a fax. When it started making noise, there was a lot of hubbub. I’d run over immediately and look to see what was coming in. That’s how the orders went.

Pavelka: The first trade show Retigo s.r.o. was at independently was a year later, in 1995. And we also travelled to Slovakia. That involved a lot of paperwork. At Bumbálka, where we crossed the border, there was a line of semis, we cleared customs, and dealt with all the papers... The trade show was at the Agrokomplex site in Nitra.

Who thought up the name for the company?

Kudela: Jirka Jaroň came up with the name Retigo. We sat down and thought about what we were going to call ourselves. “Gastro technology”, “Gastro equipment”, everybody had that, and then suddenly — RETIGO. We didn’t even do any research to see if we could use the name. We just jumped into it. The inspiration was Magdalena Dobromila Rettigová, the 19th-century author. We wanted to emphasize the Czech origin. Moreover, Magdalena was very well known — people had her cookbooks at home. I remember that the first slogan on the stand was, “Magdalena Dobromila Rettigová would be amazed.”

Was there ever tension among you that led to arguments?

Pavelka: There were little things, but nothing earthshaking. We were always aware that the company was stronger if we stuck together. Each of us had his area to take care of, and covered that. Jarek Kudela handled sales and marketing, Jirka Jaroň dealt with investment and systems, along with Vašek Miller we put together appliance design and production, and Zátopek was head of service and participated in electrical design. I handled personnel, contracts and economics. At the beginning, Jarek Kudela and I travelled to negotiate with business partners. However, we always tried to find a solution we could agree on. There were differences of opinion, but we tried to find solutions acceptable to everyone [laughs].

Paradoxically, the biggest disagreement was choosing the floor for the current entrance hall at reception. A huge discussion on whether it should be black, grey, glossy, marble, and things like that.

The journey was indeed an adventure...

Zátopek: We first travelled in my Škoda MB 1000. Among other things, my job was also purchasing electrical materials. During one purchase at a wholesaler in Olomouc, a large coil (about 2 meters in diameter) with a heavy cable fell onto my parked car. The left side was destroyed, including the door. So I tied the door to the car and drove back. The aforementioned company paid for the damage, and it cost a lot. Then to expand our cargo capacity, we bought a semi that the company is still using today, but that poor Škoda MB 1000 is long gone.

I also have several stories associated with my name. We imported heating elements from Sweden, and the Swedes were trying to get on my good side because they thought I was a relative of Emil Zátopek, the Olympic runner.

Pavelka: Once we took a combi oven to the Krkonoš Mountains to Moravská Bouda, which is in the mountains, about 1200 metres above sea level. In the morning we rode there with a cart and a combi oven. The weather was splendid and the roads were clean and dry. We installed the appliance, did the training, but in the evening we didn’t leave. Snow was falling. We didn’t have tyre chains, and there was no getting out. So sometimes it was quite an adventure.

And another incident when we went to buy stainless-steel sheets. Nobody brought us anything. We drove there and bought individual parts ourselves; trucks weren’t travelling. Colleagues carried the sheets on carts, and on the luggage rack of another car, a Škoda 120. There was such a headwind that the sheet on the roof completely bent. That’s how things went the first year.

One of the first Retigo's car

Where were the first combi ovens sold?

- Integrated Secondary School, cook, waiter, Frenštát pod Radhoštěm, CZ, model 611, date: 15.06.93 (today, Hotel School)

- OMMA department store, Frýdlant nad Ostravicí, CZ, model 611, date: 15.03.94

- Medical institution, Paseka, CZ, model 611, date: 15.04.94

- SOU spol. catering, Vítkovice Ostrava, CZ, model 611, date: 15.05.94

- TERASA restaurant, Opava, CZ, model 611, date: 20.05.94

- BEČVA bed and breakfast, Rožnov pod Radhoštěm, CZ, model 611, date: 10.07.94

- Nová huť, Kunčice, cafeteria 610, Ostrava, CZ, model 611, date: 15.07.94

- OLEA wine bar, Vinohrady, Prague, CZ, model 611, date: 20.07.94

- Retirement home, Frýdlant nad Ostravicí, CZ, model 1011, date: 13.10.94 (first model 1011)

All the aforementioned appliances were sold by the association. After Retigo s.r.o. was established, the first appliance was sold on 16 November 1994 to Moravska Bouda in Spindleruv Mlyn (CZ).

Note: The situation and conditions when the business started were influenced by the atmosphere that then reigned in Czechoslovakia and from 1993 in the Czech Republic.