Left door

The model series of combi ovens RETIGO Orange Vision was created from requirements to satisfy customers with fewer demands on the number of functions in the basic configuration, but with emphasis on high quality and easy control. Orange Vision combi ovens are equipped with an automatic cleaning system, 7-speed fan, 1-point core probe, and flap valve. The elegant functional design underscores the simplicity of devices, the LED display enables easy settings and control.

One of Retigo Vision's best-selling sizes of combi oven. The size of 1011 is ideal for operations with a capacity of 151-250 meals a day. It can accommodate (11) 13" x 18" sheet pans or (11) 12" x 20" hotel pans or (11) x 1/1 GN pans. Wide-ranging accessories can be purchased to go with the 1011 size - various types of stainless steel stands, etc. Model 1011 can be built into a set with another combi oven. The steam generation system is injection or boiler-based. The heat source is electricity or gas.

Make your diners a great reason to keep returning to your place. With Retigo Vision combi ovens, you have the peace of mind that you will always achieve outstanding cooking results. The prepared foods have a perfect color, are juicy, crispy, and healthy with minimal fat content.

Simply keeps you cooking with ease and comfort. Experience an excellent combination of features, exceptional ergonomics, and an attractive appearance. All this with a focus on safety, hygiene, and long-time reliability.

Gives you time to concentrate on cooking and things that really matter to you. The simplest controls on the market will save you time and enable you to quickly and easily make all the necessary settings. Display response is perfect even with grease or gloved hands.

Generates money on savings for you every day. In-built heat exchanger, triple glazed door glass, 50 mm thick thermal insulation combined with low consumption automatic cleaning will ensure you a great return on investment.

| Model | O 1011 i | O 1011 b | O 1011 ig |

|---|---|---|---|

| Technical specification | 2E1011IA | 2E1011BA |

2G1011IA |

| Heat source | Electricity | Electricity | Natural gas / Propane |

| Steam generation | Advanced injection (Boilerless) | Advanced boiler | Advanced injection (Boilerless) |

| Capacity | 11 x Half-size cooking pans | 11 x Half-size cooking pans | 11 x Half-size cooking pans |

| Capacity of meals | 151-250 meals per cooking cycle | 151-250 meals per cooking cycle | 151-250 meals per cooking cycle |

| Spacing | 2.6“ | 2.6“ | 2.6“ |

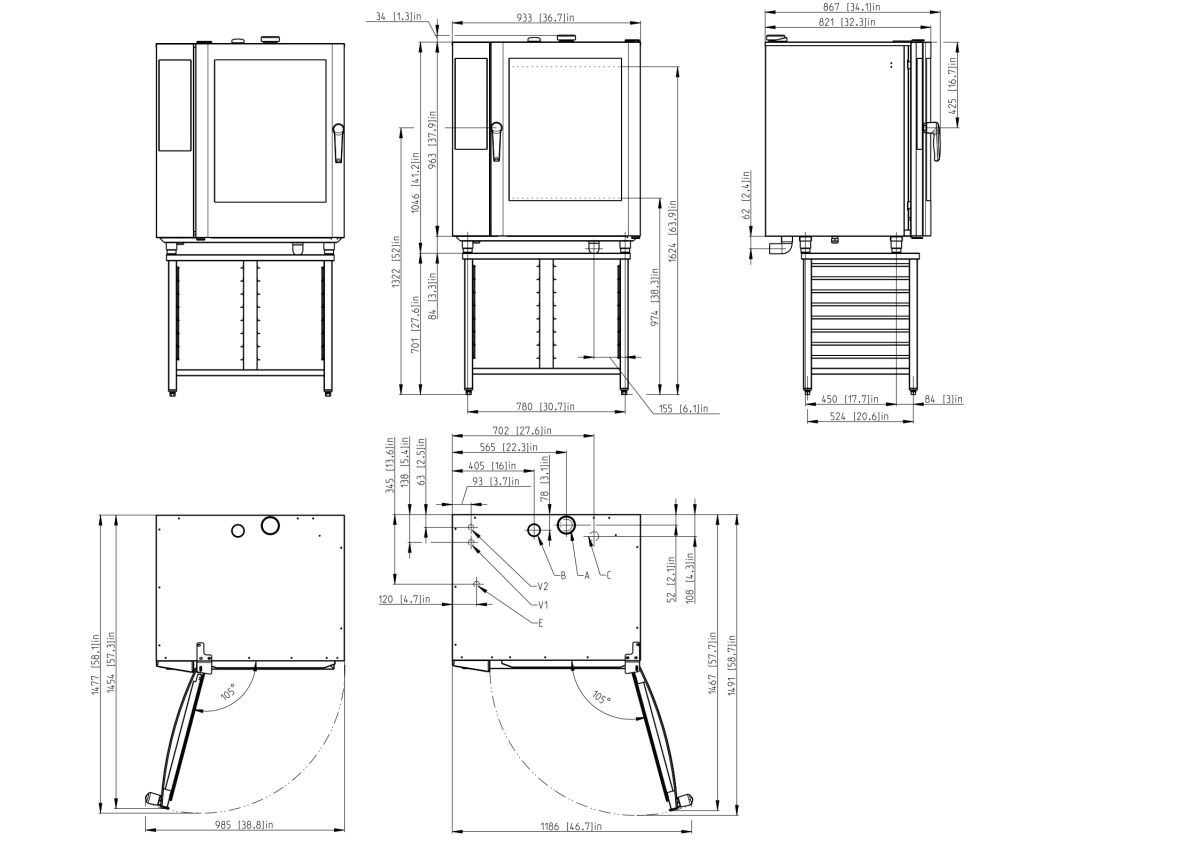

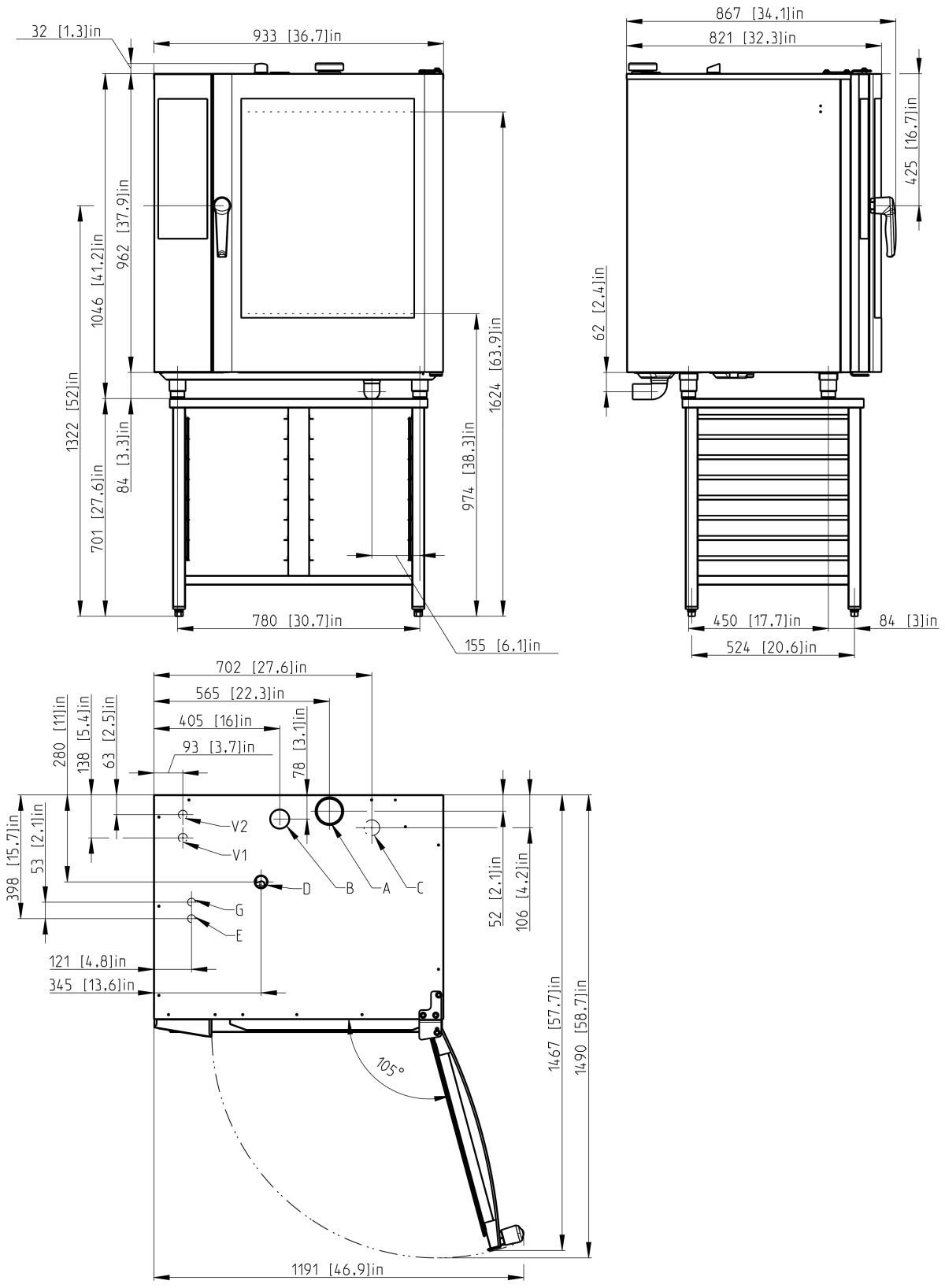

| Dimensions (w x h x d) | 36.7“ x 42.8“ x 32.3“ | 36.7“ x 42.8“ x 32.3“ | 36.7“ x 42.8“ x 32.3“ |

| Weight | 304 lbs | 316 lbs | 328 lbs |

| Total power | 15.3 kW | 15.3 kW | 0.8 kW |

| Heat power | 14.7 kW | 14.7 kW | 80,000 BTU/hr |

| Steam generator power | - | 14.7 kW | - |

| Fuse protection | 45 A | 45 A | 15 A |

| Voltage | 3~/208 V/50-60 Hz | 3~/208 V/50-60 Hz | 1~/120 V/50-60 Hz |

| Optional voltage | 3~/240 V/50-60 Hz, 3~/480 V/50-60 Hz | 3~/240 V/50-60 Hz, 3~/480 V/50-60 Hz | - |

| Noise level | max. 70 dBA | max. 70 dBA | max. 70 dBA |

| Water/Drain connection | G 3/4” / 2“ | G 3/4” / 2“ | G 3/4” / 2“ |

| Gas connection | - | - | NPT 3/4” |

| Temperature | 86 – 572 °F | 86 – 572 °F | 86 – 572 °F |

A - Flap Valve | B - Chimney | C - Drain | E - Electricity | V1 - Untreated water | V2 - Treated water

A - Flap Valve | B - Chimney | C - Drain | D - Flue gas exhaust | E - Electricity | G - Gas | V1 - Untreated water | V2 - Treated water

100 - 300 meals

300 - 500 meals

400 - 600 meals

600 - 900 meals

30 - 50 meals

51 - 150 meals

151 - 250 meals

400 - 600 meals